Cable pulling from simple straight shots to pulls with multiple bends and offsets greenlee cable pulling equipment saves time increases your efficiency and safely pulls cable where you need it to be.

Cable pulling standards.

These injuries happen when the human body is forced to work beyond its limits.

We offer large and small high tonnage diesel powered cable pulling machinery petrol and electric cable pulling winches cable pushers feeders blowers balloon line carriers blow line cable pulling rope polypropylene draw line double braided composite dyneema anti twist galvanised steel wire rope.

Complete range of products used for the installation of power cables.

Cable shall be tested both before removal from cable drums and on site with a 1 kv insulation tester 5kv for mv cables.

Cable pullers must be in good working condition their dynamometers properly calibrated and be securely mounted prior to use.

3 park avenue new york ny 10016 5997 usa.

6801 00986 ultra tugger 8 cable puller with standard force gauge.

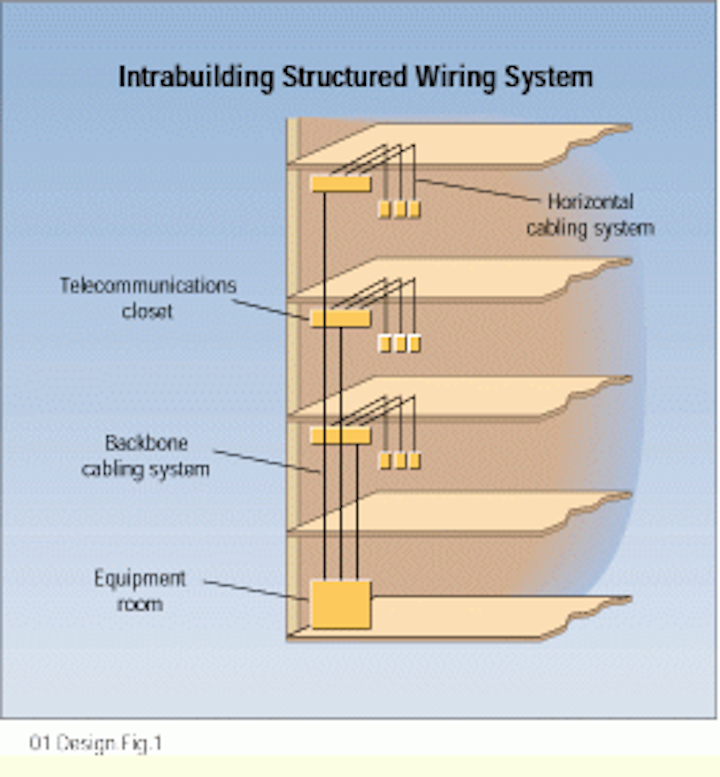

Method of installation laying of low voltage cable.

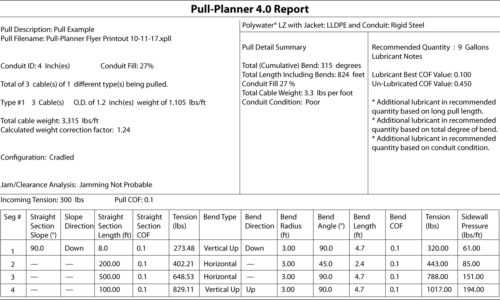

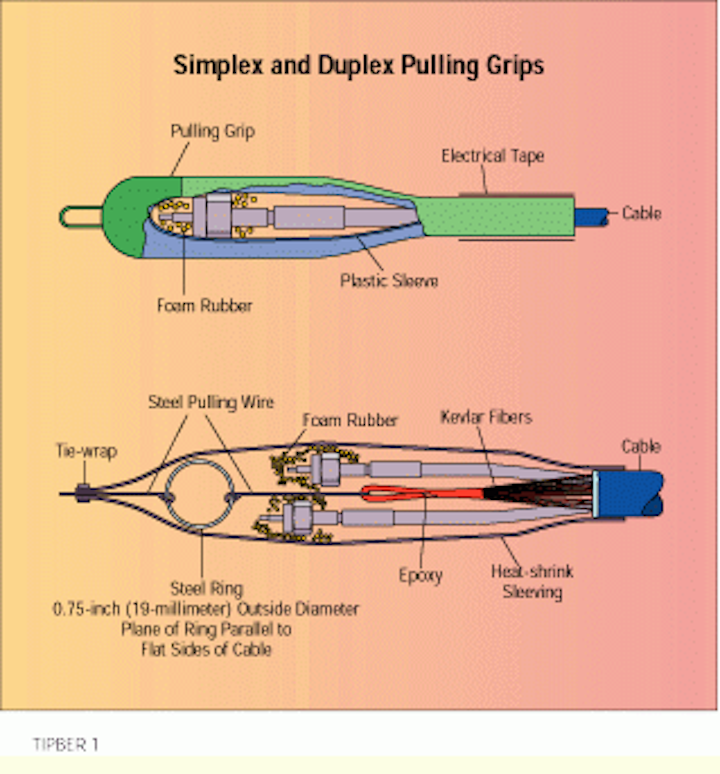

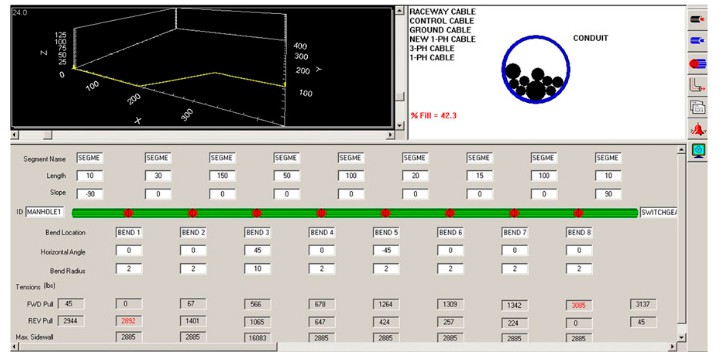

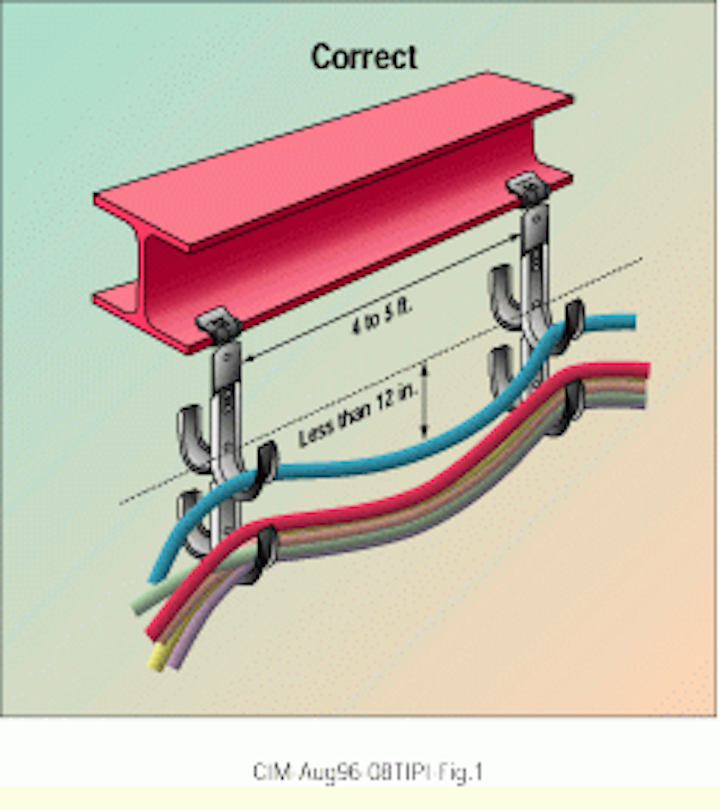

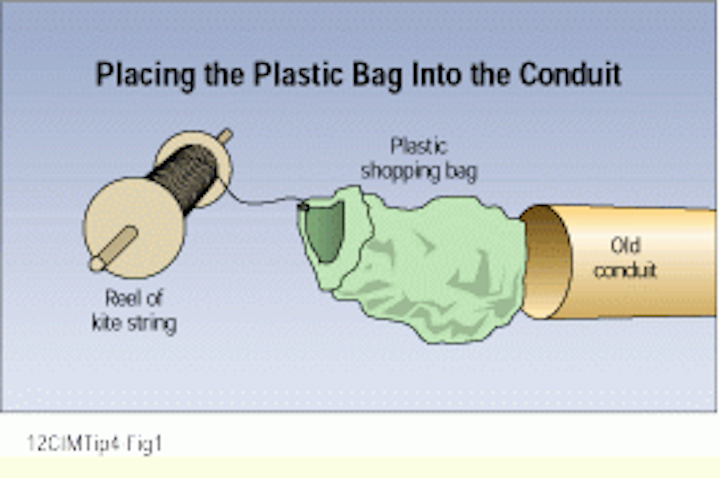

In preparing for a cable pull it is just as important to cover the small details as it is to assure that the cable does not exceed maximum sidewall pressure.

Pulling cables transcript each year in the u s 31 000 construction workers seek medical attention due to sprains and strains suffered on the job.

Ensure the cable pulling winch is placed at a suitable position according to the length of the cable and the condition of the site.

The unit lbf stands for pounds force.

A cable pulling winch is an installer s best friend when used correctly.

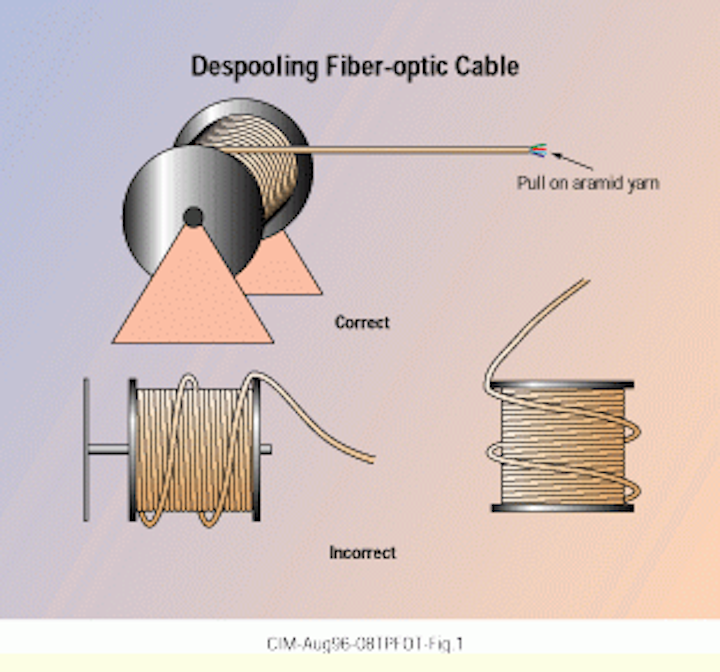

General field practices are provided to aid in preparing for large and small cable installations.

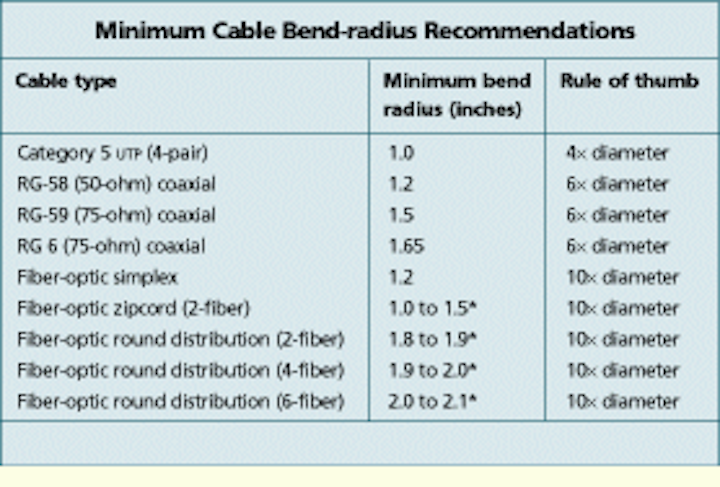

Minimum bending radii and maximum pulling tensions.

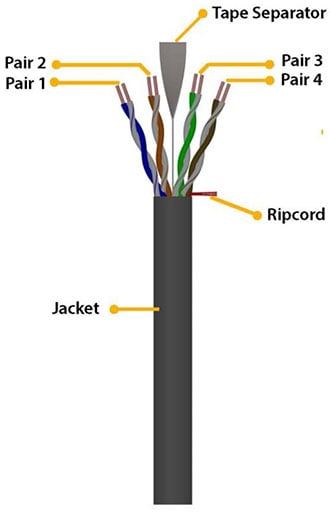

Jamming minimum bending radius pulling lubricants pulling tension sidewall pressure splicing the institute of electrical and electronics engineers inc.

Static friction between the cable sheath and the pipe walls is minimised by the grease which makes it easier to pull the cable into the pipe.

The maximum pulling tension for 4 pair 24 awg horizontal utp cables should not exceed 110 n 25 lbf to avoid stretching the conductors during installation the requirement is 110 newtons of pulling force in metric units or 25 lbs pulling force in imperial units.

Problems of installation can be avoided by designing cable layouts within the installation limits of this recommended practice.