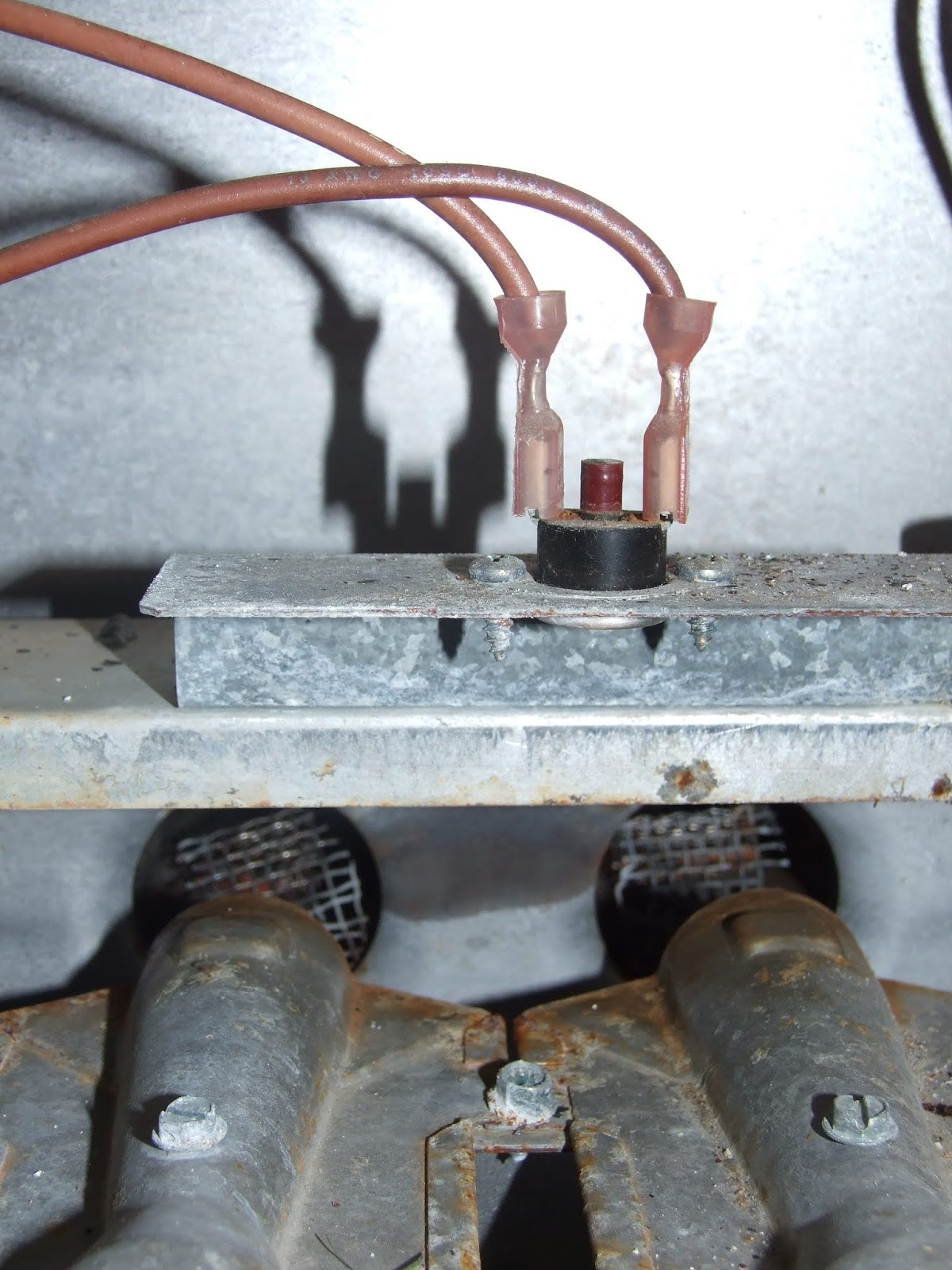

One the most common issues found in carrier high efficiency gas furnaces is corrosion or blockage is their secondary heat exchangers in approximately 5 to 10 years after the original installation date or in other words premature secondary heat exchanger failure.

Carrier furnace secondary heat exchanger problems.

The chamber becomes corroded from the inside possibly due to a reaction from acidic condensation on the polypropylene coating.

On january 3 2020 i purchased a carrier infinity 58mvc120f10120 which had the secondary heat exchanger plug up with corrosion therefore has caused numerous furnace issues over the past 3 years.

All secondary heat exchangers from replaced furnaces or whole furnaces replaced under this policy must be held at the distributor for potential factory inspection for thirty 30 days from distributor claim paid date.

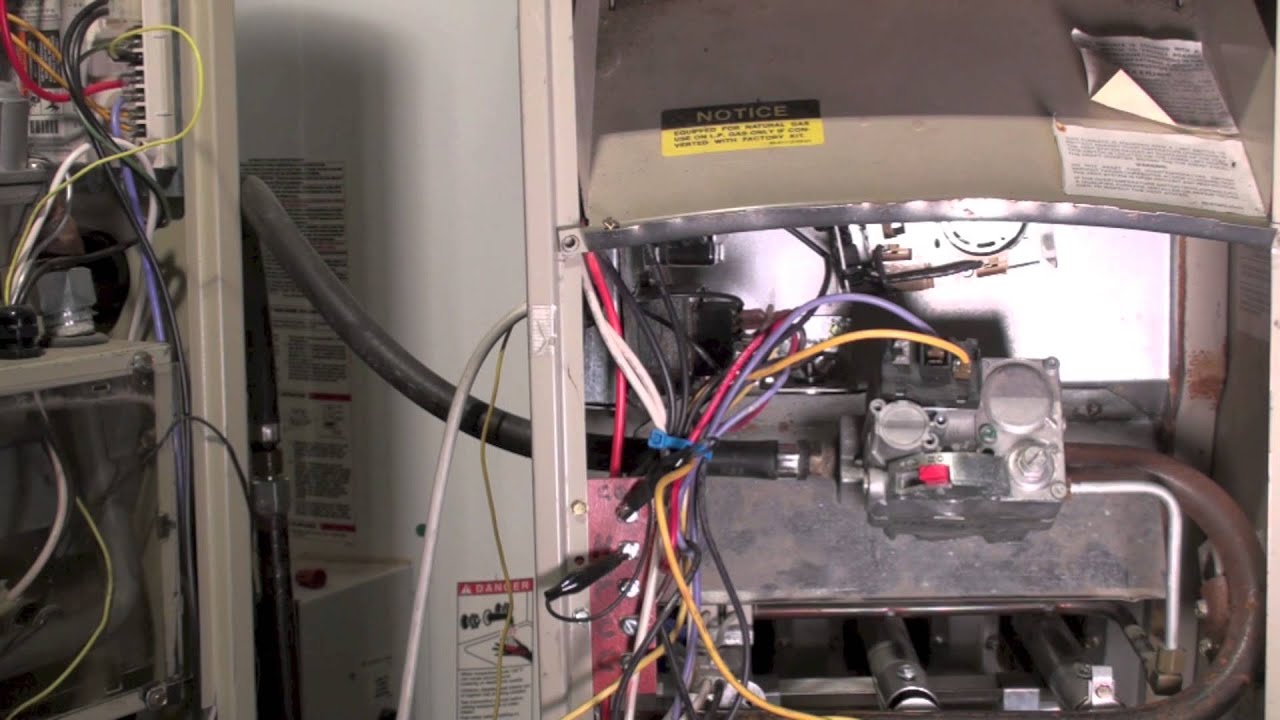

Carrier gas furnace troubleshooting step by step 1.

Sometimes the thermostat gets turned off or the setting changed by accident.

Coupling box kits cold spot baffle collector box and cell.

This problem happens due to corrosive nature of condensation water produced during combustion of natural gas and improper design in drainage system which keeps the acidic water in secondary heat exchangers exit point as shown in the.

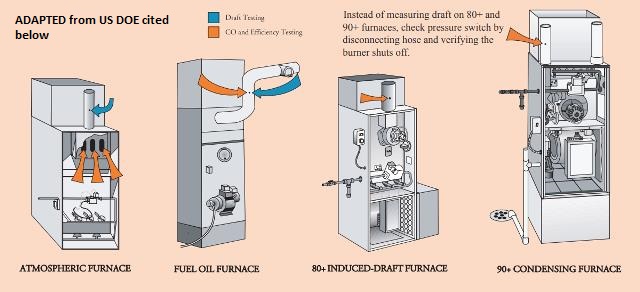

The secondary heat exchanger is designed to extract the maximum remaining heat from the fuel source resulting in a normal condensation reaction.

The program offers consumers an alternative to replacing a cracked secondary heat exchanger with significant allowances on select carrier model furnaces.

Exchanger part or furnace.